A Complete Guide to Manual Handling Safety & Training

Manual handling injuries create ripple effects throughout your organization.

Yes, they take a toll on the health and well-being of the affected worker, but the damage doesn't stop there.

These incidents slow down operations and drain your employees’ productivity and morale. Plus, resources that could fuel growth end up covering sick leave or compensation.

The HSE (Health and Safety Executive) reports that manual handling is one of the leading causes of musculoskeletal disorders, especially back pain. These injuries account for thousands of lost workdays every year and continue to hurt organizations across every sector.

That’s why proper manual handling training is critical. It equips your employees with the skills and techniques to protect themselves from injury and work more efficiently.

To help, I’ve put together a comprehensive article with actionable information that you can take back and implement right away.

Manual handling refers to any activity requiring the use of force exerted by a person.

Specific manual handling actions include lifting, lowering, pushing, pulling, carrying, moving, holding or restraining an object, person or animal.

In some cases, workers have direct contact with the object, person or animal they’re handling. But, more often than not, they have access to manual handling aids like trolleys, conveyor belts, pulleys, wheelchairs and many more.

That said, the fact that they’re using aids doesn’t mean that it’s not manual handling anymore. As long as they’re using their body to do the action, it’s considered manual handling.

Safety experts often remind us that manual handling training is about more than physical techniques:

“Manual handling is not just about strength — it’s about strategy. Save your back. Use your brain. Safety isn’t heavy, injuries are.” -Nidhija Prabhakaran from the HSE Training center,

This video from an Australian safety firm does a great job of explaining manual handling.

Manual handling training and safety induction are not the same thing. In fact, manual handling training is actually part of a safety induction.

| Manual Handling Training | Safety Induction |

| Conducted regularly for all employees | Conducted during the onboarding of new employees |

| Includes analysis of current practices to find gaps for improvement | Includes the employee's first manual handling training |

| Concentrates only on manual handling (pushing, pulling, lifting, carrying, lowering, moving things with your body) | Also covers other safety instructions, like SDS knowledge |

Manual handling training and techniques can have positive or negative impacts depending on the employer’s involvement and care.

I’ve gathered two real-life examples, one negative and one positive, to illustrate the value of proper manual handling training.

SKULD, a maritime insurance company, shared this case study of an incident reported to their club to help clients understand the risk related to improper training on manual handling.

Logistics company TAWI manufactures vacuum lifting machinery to help different industries improve their manual handling techniques.

One of their standout success stories is with Kuehne+Nagel in France.

TAWI solutions were implemented on the workfloor, resulting in several improvements in terms of health and safety.

Before implementation, workers were using manual handling for heavy packages, causing physical strain and fatigue. The issues went deeper:

TAW implemented the tech at their facility along with training for all workers. These are the actions that took place:

This is Tawi’s video about the case study:

The details in manual handling training differ according to industry, process and situation. But there is a framework you should follow regardless of your purpose.

These are the non-negotiables you must include in your manual handling training.

I’ve used a package delivery service as an example to explain how this works.

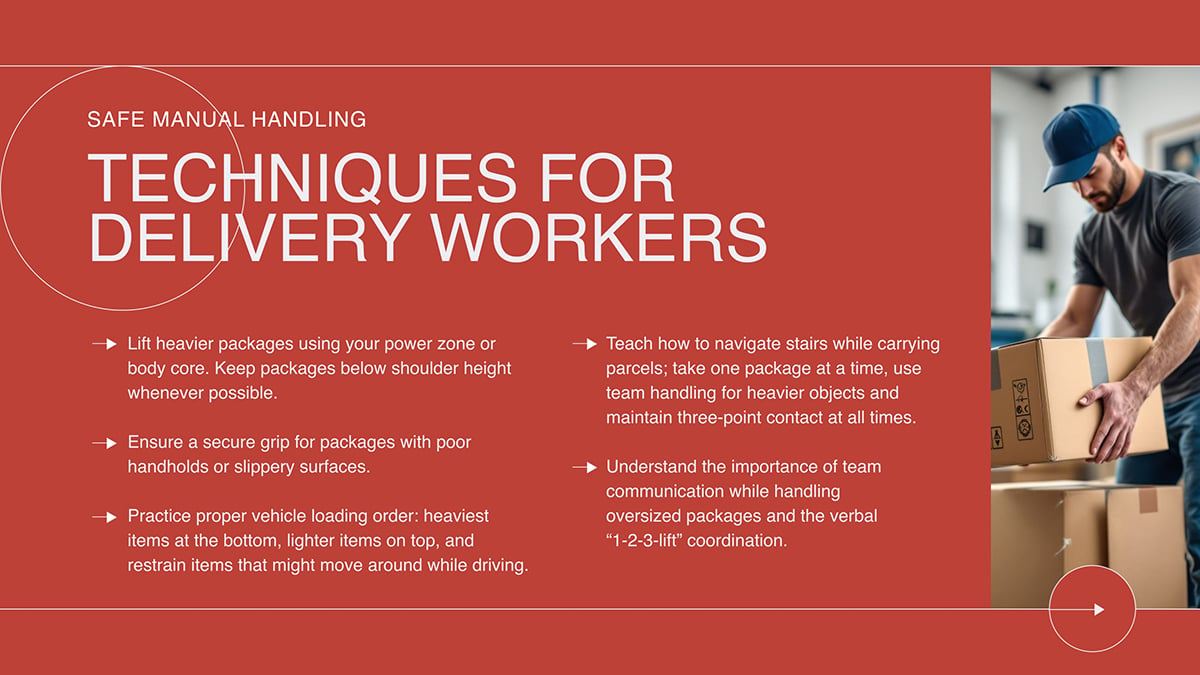

The first thing to include in the training is the exact, specific, and safe manual handling techniques your employees will use while performing their job.

Using the package delivery service example, here’s what would fall under this scope:

This industry-specific approach is crucial because generic training often falls short. As real estate entrepreneur Erik Wright learned through experience,

"No generic training videos and theoretical discussions of lifting technique will suffice because every workplace presents unique challenges, weight configurations, space constraints, and material handling requirements that influence the application of proper technique."

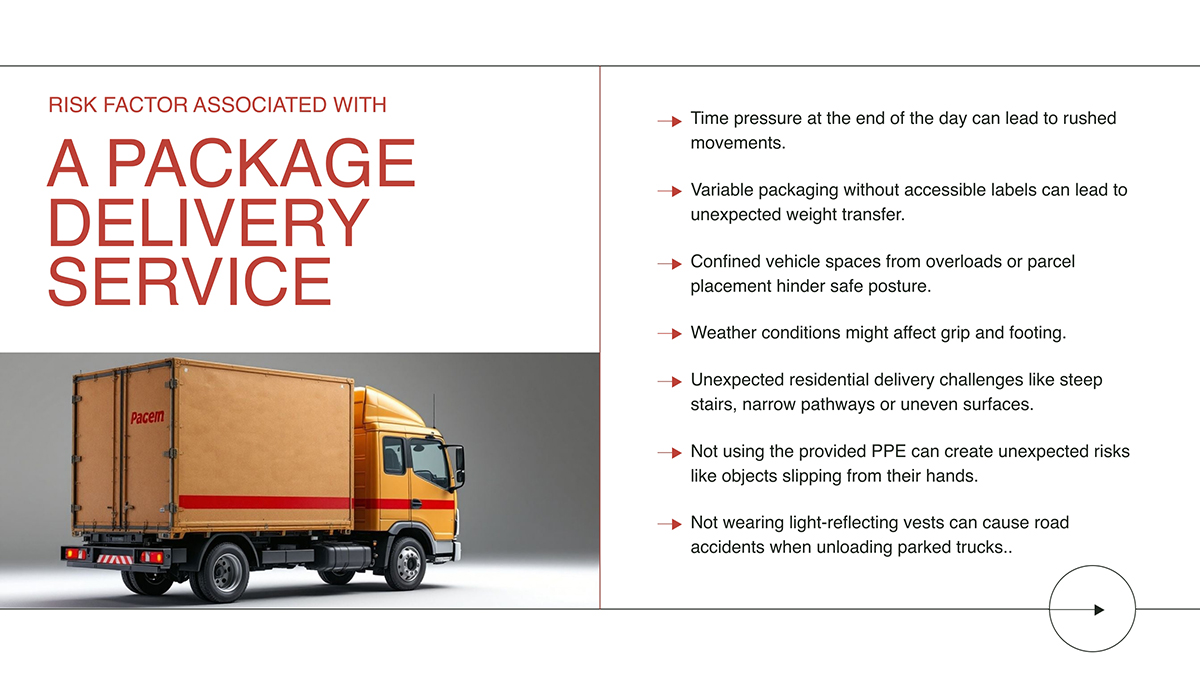

Next, explain the instructions and importance of assessing risk before any manual handling. Use the AAAR Framework to direct these decisions. They are Avoid, Assess and Adjust (Reduce).

For a package delivery service, the risk assessment typically occurs at the time of delivery. And this is how it should go:

At this stage, it’s time to offer workers the actual techniques for correct manual handling that will keep them safe while avoiding strain.

For a package delivery scenario, you’ll teach these techniques:

Hands-on practice with actual materials cannot be overstated. Wright emphasizes this point:

"One thing you cannot leave out of manual handling training is the inclusion of physical demonstrations using the actual equipment and materials your personnel will be working with daily."

This is why simulation training using real workplace materials produces better safety outcomes than theoretical instruction alone.

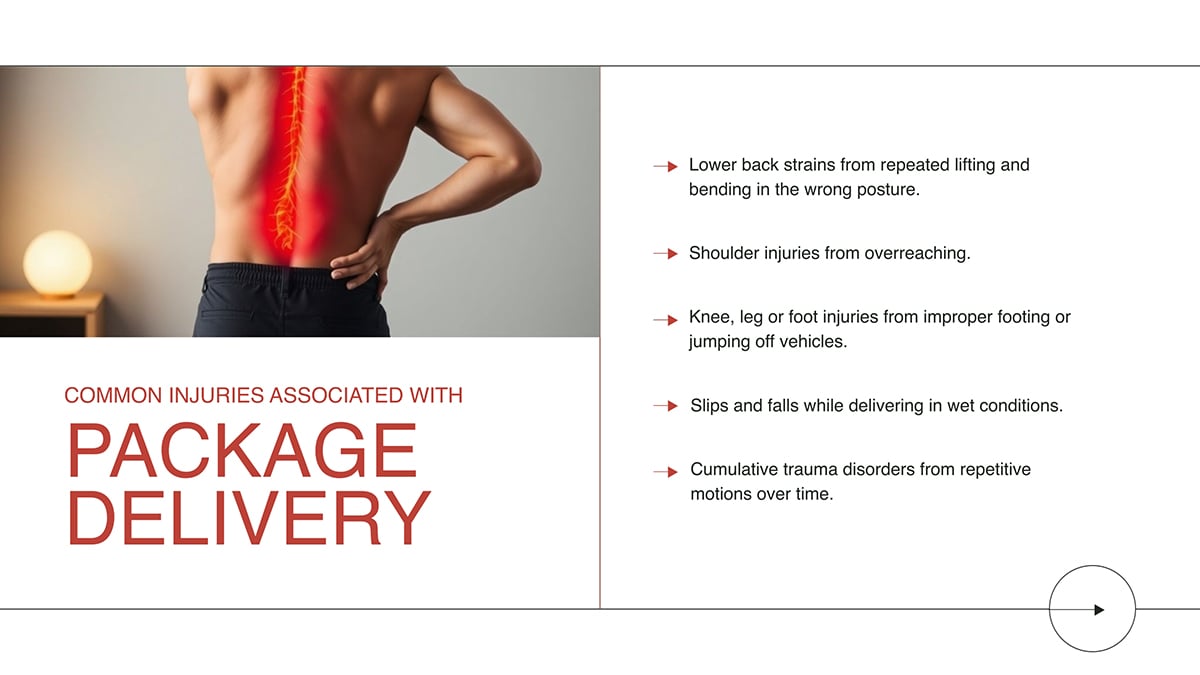

First, share with them how injuries can occur, and then demonstrate the types of injuries that can happen.

These are some of the risk factors involved with package delivery services:

Immediately after, explain the actual risks of injury, such as:

Real-world examples will effectively illustrate this point. Wright's construction team experienced exactly these types of injuries when they relied on generic training:

"One team member hurt his back by rolling a cast iron bath down narrow stairs, another injured his shoulder by lifting rubbish into our disposal units, and a third acquired repetitive strain injuries through improper use of sledgehammers when demolishing."

You’ll need to provide PPE for your workers (or offer solutions for them to easily acquire it) and demonstrate how to use and maintain it properly. Explain that it’s mandatory to use all provided PPE at all times while they’re working. This is important for both safety and legal reasons.

These are the PPE items that package delivery workers might need:

Your training program must also include emergency procedures for potential accidents. Hopefully, they won’t happen, but your workers must always know what to do and who to call.

For the package delivery workers, they’d need to:

Finally, it’s good practice to share wellness tips with your employees so that they can take care of their bodies beyond the time they spend at work. This isn’t a mandatory regulation, but including it shows that you care about your employees. Offering gym memberships or even an in-house gym would help them even more.

When I asked personal trainer Bart Konings about this, he explained that the biggest risks appear when the body is weaker than the job demands.

“Lifting and pushing heavy objects requires strength and stability. There will be circumstances where you have to be in unnatural and poor positions where being able to use a correct lifting technique is not possible,” Bart said.

That’s the reality on any shop floor. No matter how much training someone has, there are moments when perfect technique isn’t an option—awkward angles, tight spaces, or unpredictable loads. And that’s when injuries happen.

“When the demand and forces working on the body are higher than your ability, stability, strength or technique, injuries can happen, especially in the lower spine,” he explained. “Keeping the core engaged and the spine neutral while lifting heavy objects resists ‘shear forces’ on the spine and protects against lower back injuries.”

I like how he frames the core not just as muscles, but as a stabilizing system. He uses a simple analogy to explain it:

“Think of your core as a soda can. The strength comes from its shape. The top and bottom of the can must stay flat and parallel, and the wall around it has to stay smooth and unbroken. If there’s a hole or dent in the side, it will lose its strength.”

That visual reference makes it easy to understand why building strength matters. A stable core is like an intact soda can; it can withstand pressure. A weak one just collapses.

Bart also stressed that exercises targeting the core and surrounding muscles are key, and they don’t have to happen only at work. Check out his Instagram video to see how you can incorporate them into your daily life.

“There are some effective exercises that can help you strengthen your ability to engage the core and the muscles around the joints and spine. These will be beneficial for resilience in both everyday life and during more demanding work. Practicing how to lift with correct technique can also be done at home, making sure the right muscles are doing the work when moving an object.”

That said, he warned against relying on bodyweight drills alone. If you don’t challenge the muscles with resistance, you won’t be ready for the heavy demands of manual handling.

“However, if you do not include exercises with weights, you will probably still be underprepared and lack the ability to effectively engage the core and muscles correctly to protect your joints when doing demanding work with heavy objects,” he told me. “Therefore, I would strongly advise practicing lifting weights with a good technique and proper core engagement.”

And his final takeaway is one everyone should heed, whether you’re a delivery driver, warehouse worker, or office staff:

“I would advise anybody who wants to grow old with a functional and resilient body to include some form of resistance training in their routine!”

Let’s take a look at how to conduct manual handling training for employees.

Regardless of whether you’re the one doing the training or if you’re working with a professional trainer, these are the steps for conducting manual handling training in your workplace.

You’ll need to prepare training videos with handouts and other materials. Therefore, I have also included these steps.

What exactly do your employees need to handle, and under what conditions and circumstances? It’s at this intersection that you find the needs and objectives for your training program.

This step is crucial because a proper training needs analysis ensures your program targets the real gaps rather than delivering generic, one-size-fits-all sessions.

Regardless of the industry or situation, there are a few things you can do to deduce needs and objectives:

Let’s use the sports industry as an example. Your training goals and objectives should answer this question: What should athletes, coaches and assistants walk away doing differently? For example, your training objective could equip them to:

The same approach applies in other sectors: healthcare teams focus on patient transfers, warehouse workers on parcel handling or construction crews on irregular loads.

The cost of getting this wrong can be significant.

Wright learned this lesson when his team suffered three injury incidents in just six weeks, all because "the generic training had not covered the specific topics of working within tight spaces with irregular shapes, setting up lifting activities between multiple individuals, or modifying techniques for demolition equipment."

A thorough training needs assessment would have flagged these gaps early.

Depending on your specific needs and situation, select a training format and the accompanying content types that best suit your requirements.

Here’s a table that will help you figure out the best combination.

| Training Format | Content Types to Use | When to Use It | Pros | Cons |

| In-person | Projected training presentation slides, live demonstrations, printed handouts and oral/practical quizzes. | High-risk environments, complex equipment training, new employee onboarding and team-based activities. | Direct interaction and feedback, hands-on practice, immediate Q&A and team-building opportunities. | Higher costs, scheduling challenges, limited to one location and weather/travel dependencies. |

| Virtual/E-learning | Screenshared presentation slides, videos, digital training manuals, interactive content and written assessments. | Refresher training, theory-based content, geographically dispersed teams and budget constraints. | Cost-effective, flexible scheduling, easy to record and replay and reaches remote workers. | Limited hands-on practice, technology barriers, reduced engagement and internet dependency. |

| Hybrid Learning | Videos for demos, online manuals, printed materials for field use, interactive tablet experiences and both oral/written assessments. | Large organizations, mixed workforce (office/field), comprehensive programs and different learning preferences. | Best of both worlds, flexible delivery options, accommodates learning styles and scalable approach. | Complex to organize, requires multiple platforms, potential tech issues and higher coordination needs. |

| Self-paced | Online digital manuals, videos, interactive learning experiences and written assessments. | Experienced workers, refresher training, compliance requirements and shift work environments. | Individual learning speed, 24/7 availability, cost-effective for large groups and reduced trainer dependency. | No immediate feedback, requires self-discipline, limited interaction, harder to track engagement. |

| Simulation-based | Interactive tablet experiences, videos for reference, printed quick-reference guides, practical quizzes and real equipment demos. | High-risk industries, complex procedures, skills assessment and pre-deployment training. | Realistic practice without risks, repeatable scenarios, measurable results and a safe learning environment. | High initial setup costs, specialized equipment needed, maintenance requirements and space limitations. |

For our manual handling training directed at coaches and assistants, an ideal option would be in-person training that includes a presentation and live demonstrations/simulations, accompanied by a printed PDF for distribution.

The meat of the training is the content you share and explain to the attendees. In many cases, this content already exists in regulatory guidelines, instructions and other training programs.

Take a look at this example of a company’s training presentation for package delivery manual handling. There are many resources like this available online.

All you need to do is customize it for your training style, and then verify it against relevant regulations and compliance directives.

If there is no existing content for your training needs, you’ll have to write it yourself or hire a professional in manual handling.

Wright learned this lesson firsthand and now creates his own tailored materials:

"I create training aids that utilize a combination of video recording equipment and PowerPoint. I record proper body positioning for all types of materials we work with on a regular basis, create step-by-step procedures with pictures showing proper body positioning, and provide supervisors' checklists to verify technique on the job."

This approach ensures the content matches his team's exact needs. If you hired a professional to support your training, they’ll have their own content to share with your team. Coordinate with them to make the content as comprehensive as possible to reflect the manual handling actions that your workers will have to do.

For those of you creating content for your training program, here are some tips:

Aside from the textual or spoken content, you’ll most definitely need visuals ranging from simple photographs to videos and in-person simulations. Gather all the necessary materials for presentations and manuals before you begin compiling the content. Visme offers a media library where you can store and organize all your media assets, making them easily accessible and ready to use.

These are some of the visuals you’d need for the athletic coaches and assistants' training program:

If you don’t have your own visuals, access the extensive stock photo and video library in your Visme editor to support the training content. Use the search bar to find what you’re looking for. I don’t recommend you use the AI image generator for safety visuals; keep that tool for other decorative images that elevate your training resource.

This step and the next are for the creation of visual elements like videos, manuals, infographics or presentations that you’ll use as part of the training. You can start with one of the templates in the section below.

The athletic coach and assistants' manual handling training program might use a presentation as part of the discussion. However, you may need a printable manual, or if you’re in the ideation stage, a plan document.

These instructions will guide you regardless of the exact type of content you’re working on. Log in to Visme and enter the dashboard. Here you have a few choices:

Once you’ve added all the content into the document or presentation, it’s time to customize and personalize it so it matches your brand guidelines and visual identity. If you haven’t already, use the Brand Wizard with your website URL and create a brand kit within your Visme workspace.

First, personalize the colors from the template to match your brand colors. Either do it by hand or build a few branded color themes inside your Brand Area.

Regarding text and background, ensure that it’s legible by keeping the background light and the text dark; this creates good contrast and helps with accessibility. It doesn’t necessarily need to be black and white; it can be a very dark version of one of your colors over a very light version of another color. Adjust the intensity inside the color picker in the editor.

To change the fonts, select one piece of text and choose your brand font and toggle the option to change all the text in the project.

Invite team members and stakeholders into the Visme workspace to collaborate on creating and reviewing the document or presentation. Share permission for them to access the work in progress and leave comments, feedback or instructions.

Utilize our workflow management feature to assign specific tasks to individuals, ensuring they don’t miss them when contributing or reviewing.

Once all is approved and ready to go, proofread it one more time and get ready to share and publish it. With Visme, you have several options depending on how and where you’ll be conducting the training. I’ll list them here so you can choose:

Get everything ready to receive the group of attendees. Test the projector, screen or computer. Print what needs printing and put up any manual handling posters or materials for reference.

For simulations, collect all the physical items you’ll need and keep them aside. Ensure you have all the necessary PPE to demonstrate its proper use.

If you’ll be conducting the training online, ensure that your online connection is stable and that your camera is positioned well to show both your visual material and the demonstrations.

Welcome the group and conduct the training. Ensure that everyone can see the materials. Open the floor for questions and use the employees themselves for the demonstrations.

For maximum effectiveness, Wright recommends going beyond basic demonstrations:

"We rehearse lifting equipment, handling lumber in confined spaces, team lifting heavy equipment, and correct handling methods for construction and demolition equipment. New hires experience training simulations that mimic the actual conditions they will encounter."

Visme designers have created several templates to support your manual handling training strategies. To customize them, follow the steps in the section above.

Let’s take a look.

This manual handling training document outlines essential principles, safety precautions, and best practices for manual handling of a hydraulic lift. It is designed for personnel in manufacturing, warehousing, automotive repair and any environment where hydraulic lifts are used.

Since the content in the template is generalized, you just have to customize it to be specifically about your company’s hydraulic lift. That way, you can include detailed instructions with visuals. For example, emergency procedures could include images of the exact button or lever that turns off the lift.

Likewise, on the page titled “Understanding Hydraulic Lift Systems,” include an anatomy infographic of a lift. And as supplemental material, a QR code that directs the reader to the lift’s user manual.

Scaffold pulleys are common manual handling aids. You see them in construction, renovations and any situation in which a team of workers would need to move tools and materials from a low level to a higher level. Even if a scaffold pulley alleviates the strain on workers during manual handling, it’s still a tool they need to learn to use.

In fact, it’s still called manual handling. This training plan template is a guide for workers to understand how the scaffold pulley works, what the risks are and how to assess them, plus the essential techniques to function it properly and safely.

Are you wondering how you can make this training manual even better? Here’s an idea. Add a page with a diagram that explains and visualizes the manual handling process for risk assessment, set up, use, disassembly and storage of a scaffold pulley. Alternatively, attach process documentation with a link or QR code.

Earlier, when I shared the steps to conduct a manual handling training program, I said that you must do a risk assessment first. This template is just what you need to do that. Each pre-designed section and page will help you put together an analysis report for your client, your company or your department.

The specific content in this template is about chain block operations, but it’s easy to change to another topic. To visualize analysis results, use Visme’s data visualization tools like data widgets, to show the level of risk of any manual handling action. Turn to page six on this template to see how good they look when the colors are aligned with the rest of the project.

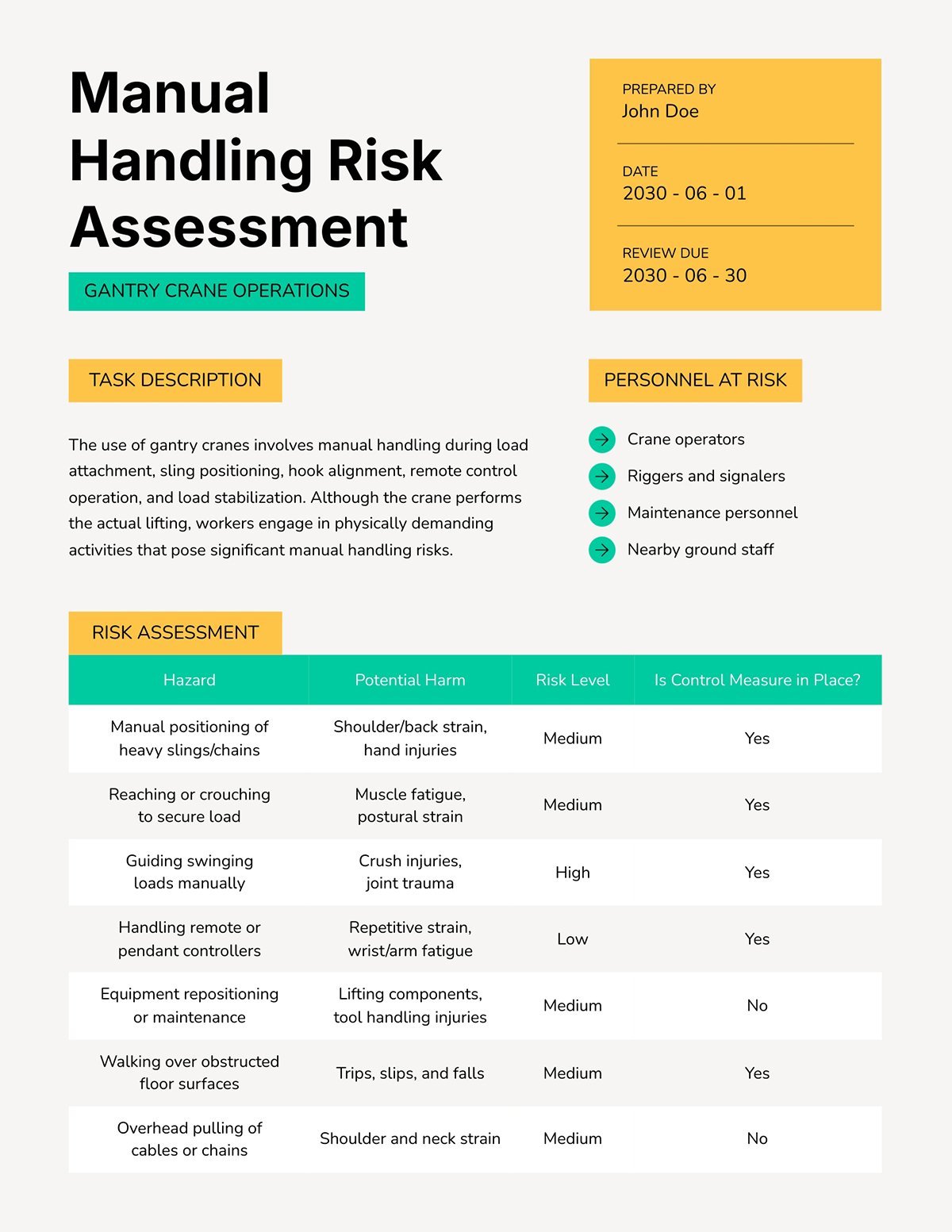

This template is also a risk assessment report, but on a single page. One pager templates are handy to get information across to a team quickly.. Aside from adding this one-pager to the rest of the safety documentation for a gantry crane, print it, laminate it and put it up on a wall close to the crane.

Alternatively, save this assessment report as a QR code and print stickers to place on all gantry cranes being used in your company. The best part of this technique is that when the risk analysts update the one-pager, you don’t need to change the QR code at all.

This template is an ideal starting point for a manual handling training document for nurses, doctors and staff at a hospital. It covers an overview of definitions, responsibilities, risk assessment and ongoing training.

Use this pre-designed document as the foundation for a set of detailed manual handling training documents. One for each group of employees (nurses, doctors, orderlies, admin staff). Visme’s Dynamic fields are the perfect tool for this situation. Add dynamic fields for content that repeats throughout documents and across versions. This way, you only need to change the exact content in the dynamic field settings and it will populate on all the content that includes that field.

Visme offers several certificate templates, including some designed for manual handling training. Use one of them, or try the AI Printable Maker to select any design and customize it to your needs and specifics.

Once your employees have completed the manual handling training, provide them with a certificate of completion as proof that they have successfully acquired all the necessary information to conduct their job effectively and safely. This template is ready to be customized with your company details and the employees’ names.

Create a safety training certificate that incorporates your brand's assets, including fonts and colors, to ensure a consistent visual identity. This template is already designed with all the content placeholders you’ll need, so all you have to do is customize and personalize.

This is another instance where dynamic fields can help. Add all the content that repeats across all certificates as dynamic fields, for example, the date, the company name, the training instructor and the type of training program.

Just as it’s important to train employees on proper manual handling, it’s also crucial to conduct regular check-ins to measure effectiveness.

Here are some ideas:

Visme Forms has resources to help you with this process. Take a look at this evaluation form, specially designed to measure training effectiveness.

And here’s a manual lifting analysis checklist template you can incorporate into your processes. You’ll need to customize it for your own situation, such as machinery or uniquely shaped materials.

Use the results to assess what techniques your employees need to retrain or relearn. This checklist will help.

Made with Visme

Aside from keeping your employees safe while handling manually, there are also legal and compliance requirements to consider. Organizations like OSHA in the US, HSE in the UK and CCOHS in Canada provide specific guidelines on their websites and through detailed documentation.

Connect with the health and safety organization in your country and follow all their guidelines and regulations. Likewise, also research the guidelines for your state or county because there might be special details you need to know.

Always subscribe to their newsletters and updates so you never miss any changes or adaptations to the rules.

With so many different types of workplaces and people in them, challenges can easily arise when planning or conducting manual handling training.

I’ve listed some of the possible challenges you might face and included solution ideas to help you overcome each particular hurdle. Some of the solutions you might not be able to conduct on your own and will need the company you work for to take care of them.

| Challenges in Manual Handling | Solutions To these Challenges |

| Employee resistance to new techniques | Demonstrate the benefit with real data. Use peer champions and success stories. |

| Language and literacy barriers | Provide multilingual materials. Use plenty of visual and hands-on demonstrations. Pair experienced workers with new employees. |

| Time constraints and production pressure | Integrate training with regular work activities. Use micro-learning and just-in-time training. Demonstrate the productivity benefits of best practices to the individuals in charge who are applying pressure. |

| Inconsistent application of techniques | Regular refresher training and coaching. Supervisor observation and feedback. |

| Outdated or irrelevant training content | Regular content review and updates. Use workplace-specific scenarios. Incorporate the latest regulatory changes. |

| Physical limitations of employees | Individual capacity assessments. Modified techniques for different abilities. Reasonable accommodation processes. |

| Equipment availability and maintenance | Preventive maintenance schedules. Adequate equipment inventory. Clear operational reporting procedures for defects. |

| Environmental hazards of workplace design | Ergonomic workplace assessments. Engineering controls and modifications. Regular housekeeping and maintenance. |

| Measuring training effectiveness | Pre and post training assessments. Workplace observation programs. Injury rate tracking and analysis. |

Manual handling training is an educational program that teaches people (employees, workers, team members) safe techniques for lifting, carrying, pushing, pulling and moving loads by hand or bodily force. The training covers risk assessment, proper body mechanics, use of mechanical aids and regulatory compliance requirements.

Effective manual handling training should:

Poor manual handling can lead to:

Manual handling training requirements vary by jurisdiction, but typically include:

The exact number of hours required for a manual handling course depends on the specific details and instructions provided.

That said, no training program will be shorter than three hours. For situations with a lot of content to cover, a course can take up to ten or twelve hours, spanning across weeks or during work processes.

Effective manual handling training is an investment in your workforce's long-term health and your organization's operational excellence. Companies that implement comprehensive manual handling programs see dramatic reductions in workplace injuries while improving productivity and employee satisfaction.

The key lies in creating job-specific, hands-on training programs that address the unique manual handling situations your employees encounter daily. This means moving beyond theoretical discussions to practical demonstrations using actual workplace equipment and materials.

Your manual handling safety program must engage employees while also staying compliant. That’s why you need the right creation tools. Visme enables you to develop visual, interactive training content that turns abstract concepts into actionable guidance.

Ready to transform your organization’s manual handling training? Explore Visme's training and development solutions to create safer, more effective workplace programs.

Design visual brand experiences for your business whether you are a seasoned designer or a total novice.

Try Visme for free